Overland Engineering and Logistics Co

Get Consultation

+1(314)377-4890

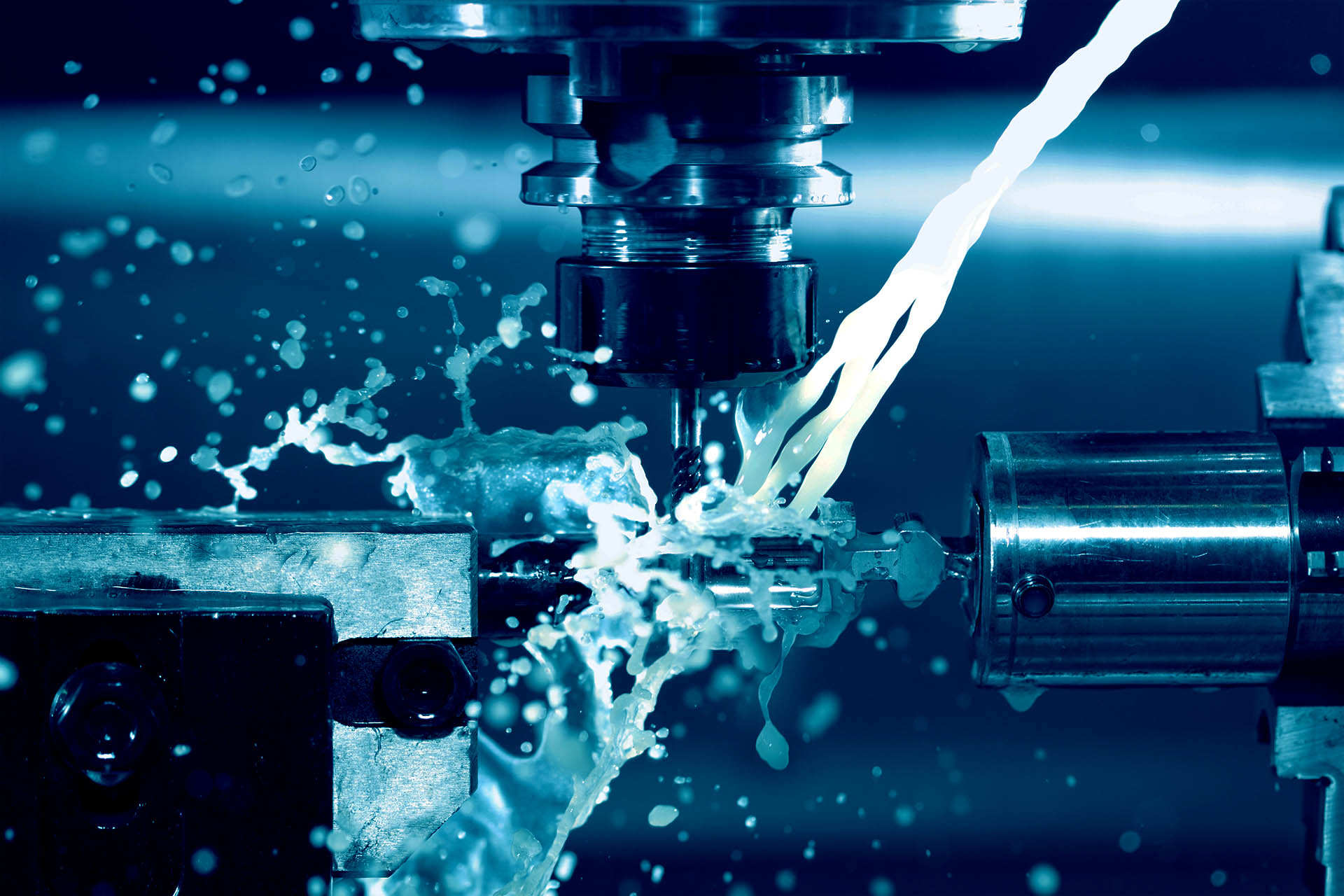

Alloy Steel, Carbon Steel

Different types of Alloy Steel

Alloy steel is a type of steel that contains additional elements mixed in with carbon to enhance its mechanical properties. These elements are added to improve characteristics such as strength, hardness, toughness, wear resistance, corrosion resistance, and hardenability. Heat treatment may be necessary to achieve the desired improvements in these properties. Alloy steel is a modified form of carbon steel, engineered to exhibit superior performance and versatility in various applications. By incorporating different alloying elements, alloy steel offers a wide range of options to tailor its properties to specific requirements.

AISI 4140 (SCM 440, 42CrMo4)

One of the most commonly used alloy steels in CNC machining services is a versatile material that offers a balanced combination of machinability, strength, and stiffness. It possesses good weldability, making it suitable for structural applications. This alloy steel finds extensive usage in the manufacturing of shafts, transmission components, gears, molds, and cold-forged automotive and industrial spare parts. Its excellent mechanical properties and adaptability make it a preferred choice for various machining operations, ensuring high-quality and reliable components for diverse industries.

AISI 4340 (SNCM 439, 40CrNiMoA)

In the heat-treated condition, this alloy steel exhibits exceptional toughness and strength, making it highly suitable for demanding applications. In its annealed condition, it offers excellent ductility and formability, allowing for easy shaping and fabrication processes. With average machinability and welding capability, this alloy steel offers versatility in various manufacturing operations. It finds primary usage in critical components such as power transmission gears and shafts, aircraft landing gear, and other structural parts. Its superior mechanical properties and adaptability make it a favored material for industries that require robust and reliable components under demanding conditions.

AISI 8620 (SCNM 220, 21NiCrMo2)

In the industrial bearing applications, a common alloy steel is employed, known for its high hardness and excellent resistance to corrosion. This alloy steel exhibits remarkable contact fatigue strength, especially after undergoing carburizing treatment. Interestingly, even after the carburizing process, the core of the component retains its toughness and malleability. This alloy steel is extensively utilized in various internal engine components, suspension parts, bushings, and automotive parts. Its outstanding mechanical properties and ability to withstand harsh operating conditions make it a preferred choice for industries that require reliable and durable bearing solutions.

AISI 4115 (SNCM 415, 15CrMo5)

Generally carburized for use, surface hardness can be between HRC 56-60 after case hardening. Mostly used as piston, transmission shaft and gear, spindle.

Diverse Carbon Steel Types

In simple terms, carbon steel refers to a type of steel that contains carbon in a concentration of less than 2.1% by weight. It is commonly used to describe steel that is non-stainless. As the carbon content increases, carbon steel exhibits improved machinability and can be hardened and strengthened through heat treatment. However, higher carbon content can result in reduced ductility.

AISI 12L14 (JIS SUM24L, DIN 9SMnPb36, free cutting steel)

Free cutting steel, also known as AISI 12L14, is renowned for its exceptional CNC machining capability. When dosed with lead, its machinability is significantly enhanced. It can be subjected to case hardening treatment, resulting in a surface hardness of HV450. This type of steel is available in square, round, and hexagon forms, offering versatility in various applications. It finds widespread use in the manufacturing of shafts, bolts, valves, bushings, pins, fittings, machine screws, surgical and dental instruments, specific automotive components, and instruments, among others.

AISI 1215 (JIS SUM23, DIN 9SMn36, free cutting steel)

AISI 1215 is a type of free machining steel that has been resulphurized and rephosphorized, resulting in excellent machinability. When machined, it produces small chips, which aids in the machining process. To enhance its resistance to corrosion, AISI 1215 steel can be nickel plated, chrome plated, or zinc plated. It is primarily supplied for heavily machined components and parts that experience low stress levels and minimal shock loading.

AISI 1015 (JIS S15C)

AISI 1015 is a commonly utilized low carbon steel known for its favorable properties. While it has lower strength compared to medium carbon steel, it exhibits good toughness, weldability, and punching press properties. This makes AISI 1015 suitable for manufacturing applications such as chain production, rivets, bolts, and shafts. Its combination of properties makes it a reliable choice for applications that require a balance between strength and workability.

AISI 1045 (JIS S45C)

Medium carbon steel is a commonly employed type of steel known for its advantageous properties. It exhibits good wear resistance and high strength, making it suitable for demanding applications. Through heat treatment, it can be hardened to achieve a surface hardness of up to HRC 45. This versatility allows for its wide usage in mechanical parts and structural steel components. Common applications include sleeves, automobile shells, pistons, steam turbines, machine shafts, worms, gears, crankshafts, and spindles. The combination of wear resistance, strength, and machinability makes medium carbon steel a reliable choice for various industrial applications.

AISI 1144 (JIS SUM43, free cutting medium carbon steel)

A commonly utilized medium carbon steel is known for its enhanced machinability, thanks to the inclusion of sulfur. This type of steel is commonly referred to as free cutting medium carbon steel. In addition to its improved machinability, it also exhibits good wear resistance and high strength. It finds primary application in the manufacturing of transmission components, including gears, shafts, bolts, valves, bushings, pins, fittings, spring seats, and machine screws. Moreover, it is used in surgical and dental medical components, automobile parts, industrial instrument spare parts, and more. The combination of machinability, wear resistance, and strength makes this medium carbon steel a preferred choice for various industrial sectors.

JIS SK4 (SK95)

High carbon tool steel, characterized by a carbon content ranging from 0.9% to 1.0% by weight, is renowned for its exceptional toughness, high strength, and excellent wear resistance. It exhibits high hardenability, allowing it to attain a minimum hardness of HRC 62 when tempered. Additionally, it experiences minimal deformation during the quenching process. This type of steel finds wide application across various industries, including the manufacturing of regular springs, spiral springs, knitting needles, horns, measuring tapes, pins, shafts, plug gauges, and washers. Its unique combination of properties makes high carbon tool steel a preferred choice for applications requiring durability, strength, and wear resistance.

JIS SK5 (SK85, spring steel)

JIS SK5 is a widely used high carbon tool steel that contains approximately 0.8-0.9% carbon by weight. It is known for its exceptional toughness, high strength, and good anti-corrosion properties. With high hardenability, it can be tempered to achieve a minimum hardness of HRC 62, while experiencing minimal deformation during quenching. To enhance the springiness of machined parts made from JIS SK5, tempering treatment is necessary. This type of steel is commonly supplied for various industrial components, including automobile parts, blades, regular springs, clips, and washers. Its combination of toughness, strength, anti-corrosion properties, and springiness makes JIS SK5 a reliable choice for a range of industrial applications.

JIS SK7 (SK65, spring steel)

JIS SK7 is a widely used high carbon tool steel that contains approximately 0.6-0.7% carbon by weight. It is known for its high hardenability, allowing it to achieve a minimum hardness of HRC 59 when tempered. During the quenching process, JIS SK7 experiences minimal deformation. Tempering treatment is necessary to enhance the springiness of machined parts made from this steel. It is commonly supplied for a variety of industrial components, including automobile parts, coil springs, clip springs, and washers. The combination of high hardenability, minimal deformation, and improved springiness makes JIS SK7 a preferred choice for these industrial applications.

Carbon steel

Free Cutting Steel: This type of steel facilitates the operation of CNC lathes with automatic feeding systems, allowing them to run autonomously without the need for human intervention. This not only enhances efficiency but also provides economic benefits. By eliminating the need for constant human interaction, the production process becomes more streamlined and cost-effective.

Overland Engineering and Logistics Co., Ltd. was established in 2011. With over 13 years of overseas experience, we provide end-to-end solutions from inception to completion.

Hotline : +1 (314)377-4890

Phone

+1 (314)377-4890

oel@overlandind.com

Location

4338 Bridgeton Industrial Drive Bridgeton MO 63044 US

Quick Links

Customer Service

Subscribe Newsletter

Copyright © Overland 2024. All rights reserved.