Overland Engineering and Logistics Co

Get Consultation

+1(314)377-4890

- Need Free Consultation ?

Get Consultation

+1(314)377-4893

Case study

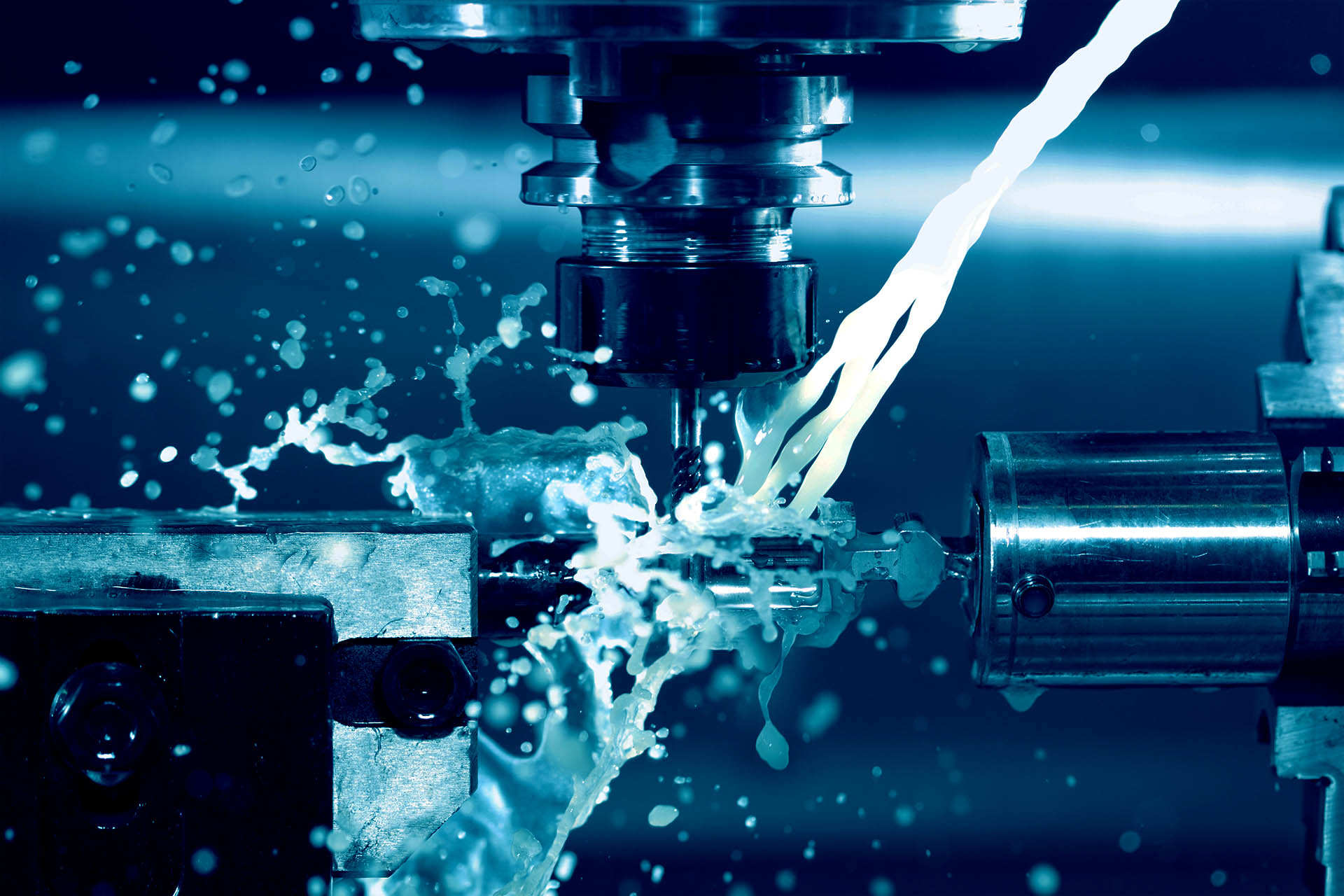

Understanding the Process of Stainless Steel Passivation.

Stainless Steel Durability Enhanced Through Passivation Treatment

One of the most frequently asked questions from our customers is why stainless steel requires passivation treatment when it already has good anti-corrosion properties. It may seem that workpieces after passivation treatment only appear more polished and completely degreased on the surface. In reality, if we only degrease and dry the workpieces without passivation, there is no noticeable difference visually. Therefore, here at Overland, we aim to thoroughly discuss and explain passivation treatment from a professional perspective.

What is Passivation Treatment?

Passivation treatment is a chemical post-treatment process designed to enhance the inherent anti-corrosion properties of stainless steel. It differs from traditional metal pickling, which removes oxide layers from the surface, and from chemical film treatments applied before coating. After passivation, a protective oxide film forms on the surface of the stainless steel workpiece. This film is extremely thin, with a thickness of less than 0.0000001 inch, roughly 1/100,000th the thickness of human hair. Generally, workpieces treated with passivation are clean, bright, and resistant to rust.

This oxide film naturally forms when the workpieces are exposed to oxygen in the air after manufacturing, polishing, or acid cleaning. Under ideal conditions, the surface is completely covered with this oxide film. However, it can also become contaminated with iron particles from cutting tools, rust, or ferrous particles produced during manufacturing. Although stainless steel items appear smooth and clean, these invisible particles can potentially cause corrosion and degrade the quality of the protective oxide film. In some cases, rusty spots may even be visible.

Additionally, to facilitate the removal of iron chippings from cutting tools, AISI 303, known as free-cutting stainless steel, includes sulfides. However, these sulfides can also lead to rust and rusty spots when exposed to certain environments.

When Is Passivation Treatment Necessary?

Overall, several unavoidable factors during manufacturing can sometimes lead to rust and rust spots on the surface of stainless steel. If the application has stringent requirements, such as exposure to high salinity, strong acids or bases, corrosive chemicals, extreme temperatures, or high humidity, passivation treatment is recommended. Alternatively, using medical-grade stainless steel AISI 316L may be appropriate. This grade is commonly employed in some of the most demanding environments, including the medical, food, energy, construction, and agricultural industries.

Overland Engineering and Logistics Co., Ltd. was established in 2011. With over 13 years of overseas experience, we provide end-to-end solutions from inception to completion.

Hotline : +1 (314)377-4890

Phone

+1 (314)377-4890

oel@overlandind.com

Location

4338 Bridgeton Industrial Drive Bridgeton MO 63044 US

Quick Links

Customer Service

Subscribe Newsletter

Copyright © Overland 2024. All rights reserved.