Overland Engineering and Logistics Co

Get Consultation

+1(314)377-4890

Our key Service

Additional Service

Stamping

Manufacturing Lines for Stamped Components

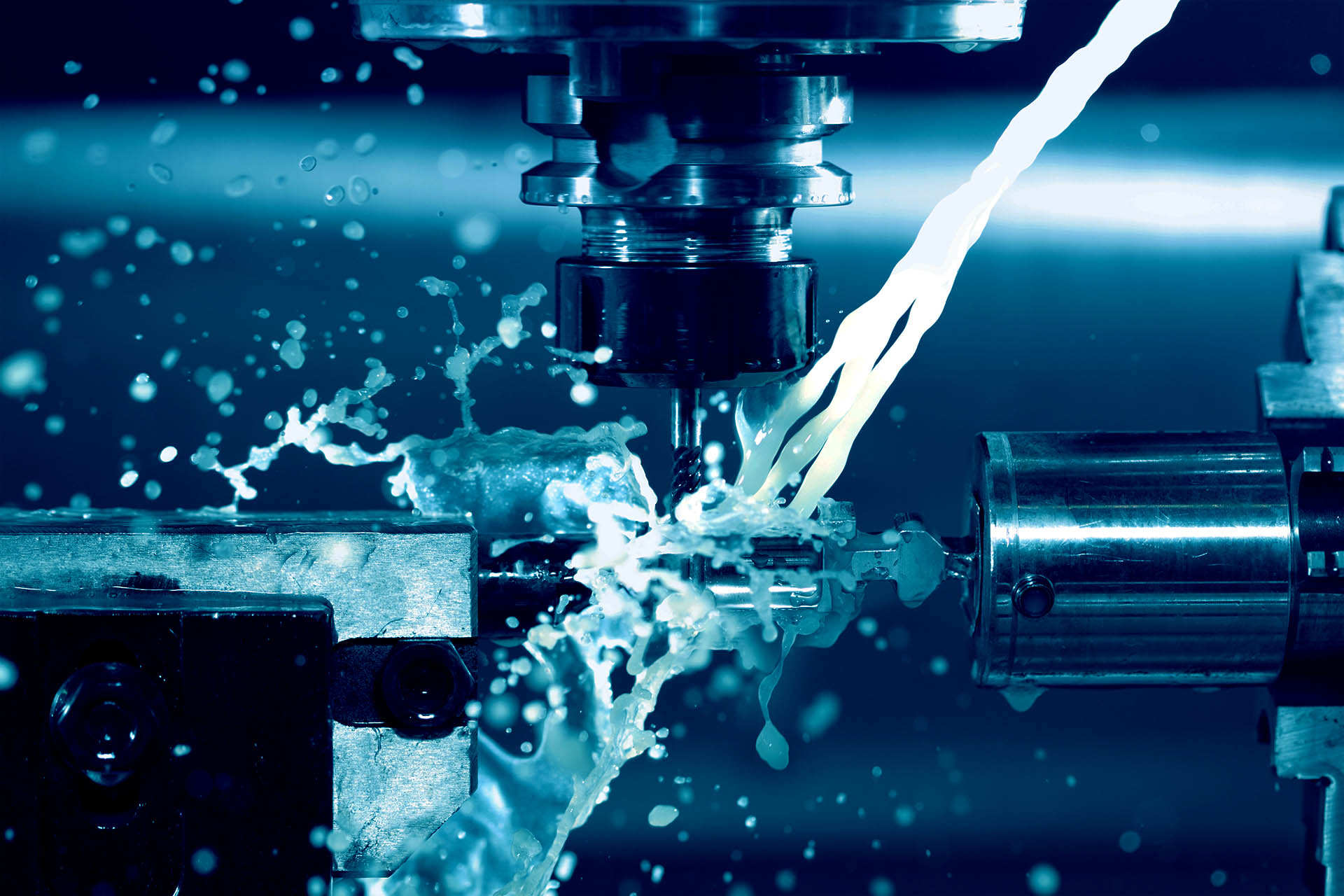

As a comprehensive machining services provider, we’ve expanded our capabilities to include a stamping facility equipped with high-speed presses, mechanical presses, and pneumatic presses ranging from 3T to 110T. This includes a dual-spindle 110-ton pneumatic stamping machine, enabling us to offer a wide range of stamping production services, including deep drawing, blanking, bending, and more.

Moreover, we’ve enhanced our stamping production lines by incorporating NCT automatic punching, laser cutting, and laser welding services, further broadening our offerings to meet the diverse needs of our clients.

What is a Stamped Component ?

A stamped part produced through stamping molds is utilized to shape metal through processes such as blanking, piercing, drawing, bending, and embossing. Both single-stage and progressive stamping molds can achieve the desired metal form with each stroke of the press.

Single-stage stamping molds, characterized by their simple structure and lower cost, are typically designed and fabricated for individual stamping operations.

Progressive stamping molds consist of a series of dies for consecutive stamping operations, with a metal strip passing through each stage per punch. While progressive stamping molds are more expensive than single-stage molds, they are often recommended for high-volume production or complex workpieces. Reach out to our team for a project review, where our engineers will provide detailed assessment and advice.

- Deep Draw Stamping

In the stamping process, sheet metal is drawn radially into forming dies through continuous mechanical action from multiple punches. This method transforms the shape of the material while retaining its integrity. The process is classified as “deep” drawing when the depth of the drawn part surpasses its diameter.

- Blanking Stamping

A stamping process involving shearing cutting utilizes a punch and die to shape the hole profile on a metal sheet.

- Bending Stamping

To fabricate V-shaped, U-shaped, or channel-shaped configurations along a linear axis in pliable materials, typically metal sheets.

Material Options for Stamping:

Copper: | OFC, C11000 |

Brass: | C2680 |

Phosphor Bronze: | C5191 |

Stainless Steel: | 304, 316 |

Aluminum Alloy: | 5052 |

Plastic Injection Moulding

To consistently produce workpieces through a repeated molding process, hot molten plastic resin is injected into a mold cavity. The resin then transitions from a liquid phase to a solidified state during the cooling phase before being ejected by ejection pin

Plastic ABS, Nylon(PA, PA66), PS, PP,

PE,POM(Delrin),PPS, PEEK, TPR, etc.

For a complimentary project evaluation of your precision plastic injection molding components, please reach out to us!

Die Casting

Aluminum Die Casting

A356, ADC 10, ADC 12

Zamak

In Addition To CNC Machining Services

In addition to parts manufactured through CNC machining, an instrument or machinery can be assembled using a diverse array of spare parts. For instance:

- Frame chassis and support structures, crafted from metal sheets through stamping machines.

- Electrical insulators, instrument chassis, or chemical-resistant containers, molded from plastic using plastic injection molding.

- Electronic connectors/housings, light shells/heatsinks, and device brackets, manufactured from aluminum through die casting molding.

As a comprehensive provider of all parts manufacturing services, including tooling for plastic injection, die casting, and stamping, Overland serves as a one-stop shop. Our R&D team boasts extensive manufacturing experience and expertise, and our clients consistently praise the exceptional quality of our machining craftsmanship.

Contrasting Stamping, Casting, and Injection Molding with CNC Machining

CNC machining isn’t the sole method for mass-producing large-scale precision parts. We offer various production methods to complement our core services:

Stamping:

- Shapes parts from metal sheets with limited thickness options.

- Allows for quick and efficient forming of parts in each step.

- Progress stamping molds are ideal for high-speed, complex, or small parts production.

- Generally more cost-effective than CNC manufacturing for large-scale production.

- Deep drawing molds provide flexibility for sheet metal forming.

Aluminum Die Casting:

- Offers an alternative to 5-axis CNC for metal forming, although parts may have off-mold angles.

- Suitable for producing thin shells, heat sinks, and complex profiles.

- Often more cost-effective than CNC machining for large-scale production.

- Capable of various surface treatments, such as nickel plating and powder coating.

- Production speed of aluminum die casting can be significantly faster.

Injection Molding:

- Provides an alternative to 5-axis CNC for plastic forming, though parts may have off-mold angles.

- Typically more cost-effective than CNC machining for large-scale production.

- Offers higher production speed compared to CNC.

- Capable of manufacturing parts from thermoplastic compounds with excellent properties.

While CNC-produced parts generally offer superior strength, quality, and finish, CNC machining is typically employed throughout all stages of project development, from initial sampling for functional accuracy to final mass production.