Overland Engineering and Logistics Co

Get Consultation

+1(314)377-4890

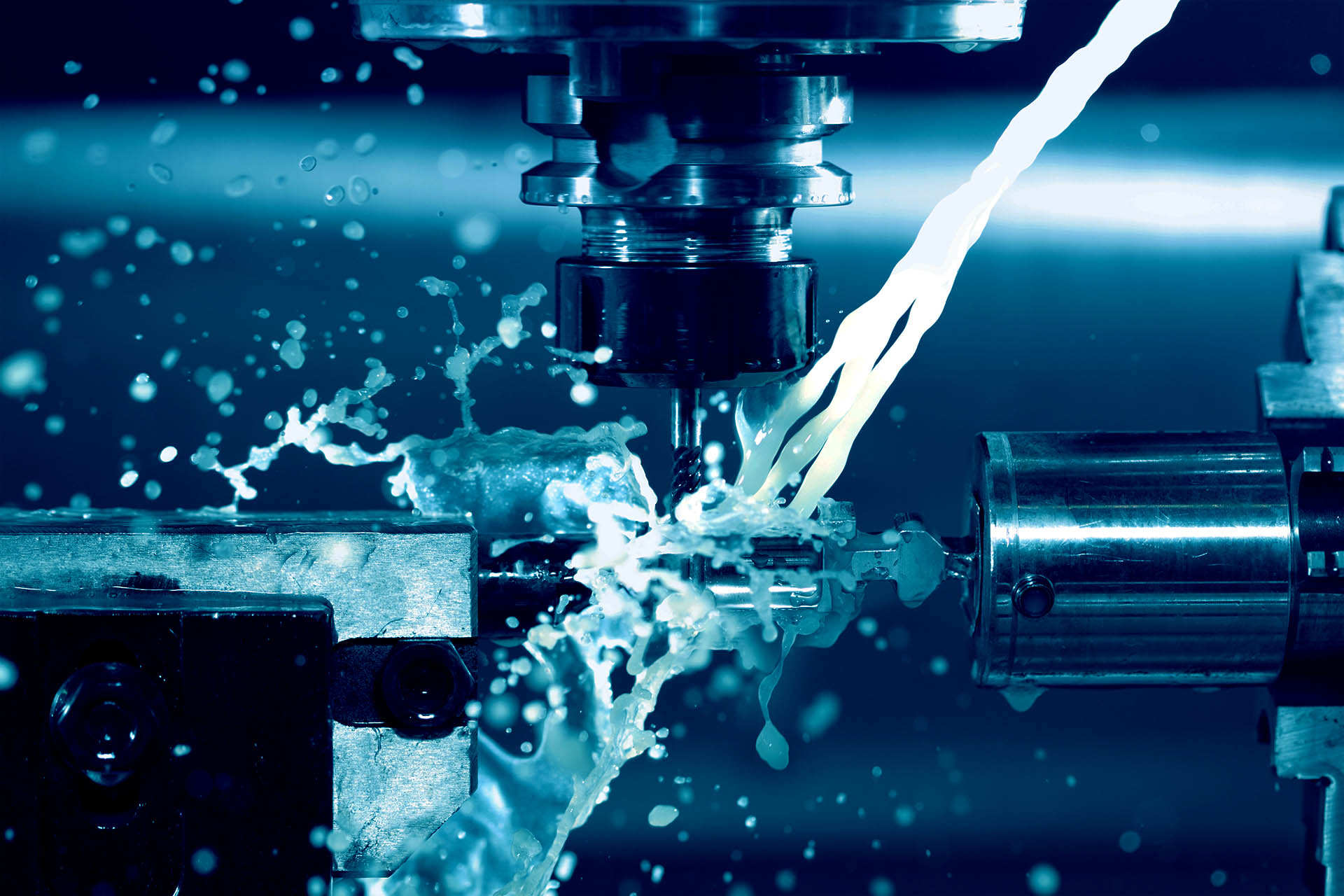

Aluminum Alloy

Overland commonly supplies and utilizes the following aluminum alloys:

Aluminum 1050

This aluminum alloy is a commercially pure grade from the 1XXX series. It is highly malleable and can be easily formed through extrusion or rolling. It finds widespread application in the electrical and chemical industries due to its excellent electrical conductivity, corrosion resistance, and workability.

Aluminum 2024

This aluminum alloy is commonly employed in applications that demand a high strength-to-weight ratio and good fatigue resistance. It can be welded using friction welding and has moderate machinability. The alloy 2024 finds extensive use in aircraft structures, particularly in tension-loaded components such as wings and fuselage structures.

Aluminum 5052

The most commonly used aluminum alloys in sheet metal fabrication, including stamping, laser engraving, and wire cutting, exhibit excellent machinability in bending, punching, and shearing processes.

Aluminum 6061-T6

This aluminum alloy boasts excellent CNC machining capabilities and weldability. It is the go-to choice for general-purpose applications and finds extensive use in aerospace construction, device frames and housings, utility boats, bicycle frames, and components. It is frequently utilized in extrusions and hot forging processes for automotive and industrial spare parts.

Aluminum 6063-T5

This aluminum alloy exhibits favorable mechanical properties and is highly weldable. It is predominantly utilized in the form of extruded shapes for architectural applications, specifically for window frames, door frames, customized frame profiles, piping, tubing, and furniture.

Aluminum 6082

This aluminum alloy offers excellent CNC machining capabilities and weldability. It is a popular choice for general-purpose applications, with widespread usage in aerospace construction, device frames and housings, utility boats, bicycle frames and components. Additionally, it is commonly employed in the production of automotive and industrial spare parts.

Aluminum 7075

This aluminum alloy is characterized by its strength, good fatigue resistance, and moderate machinability. However, it is not suitable for welding and tends to have a higher cost. It is commonly employed in the aerospace industry for applications such as aircraft wings and fuselages, as well as in the manufacturing of rock climbing equipment and bicycle components.

Overland Engineering and Logistics Co., Ltd. was established in 2011. With over 13 years of overseas experience, we provide end-to-end solutions from inception to completion.

Hotline : +1 (314)377-4890

Phone

+1 (314)377-4890

oel@overlandind.com

Location

4338 Bridgeton Industrial Drive Bridgeton MO 63044 US

Quick Links

Customer Service

Subscribe Newsletter

Copyright © Overland 2024. All rights reserved.