Overland Engineering and Logistics Co

Get Consultation

+1(314)377-4890

- Need Free Consultation ?

Get Consultation

+1(314)377-4890

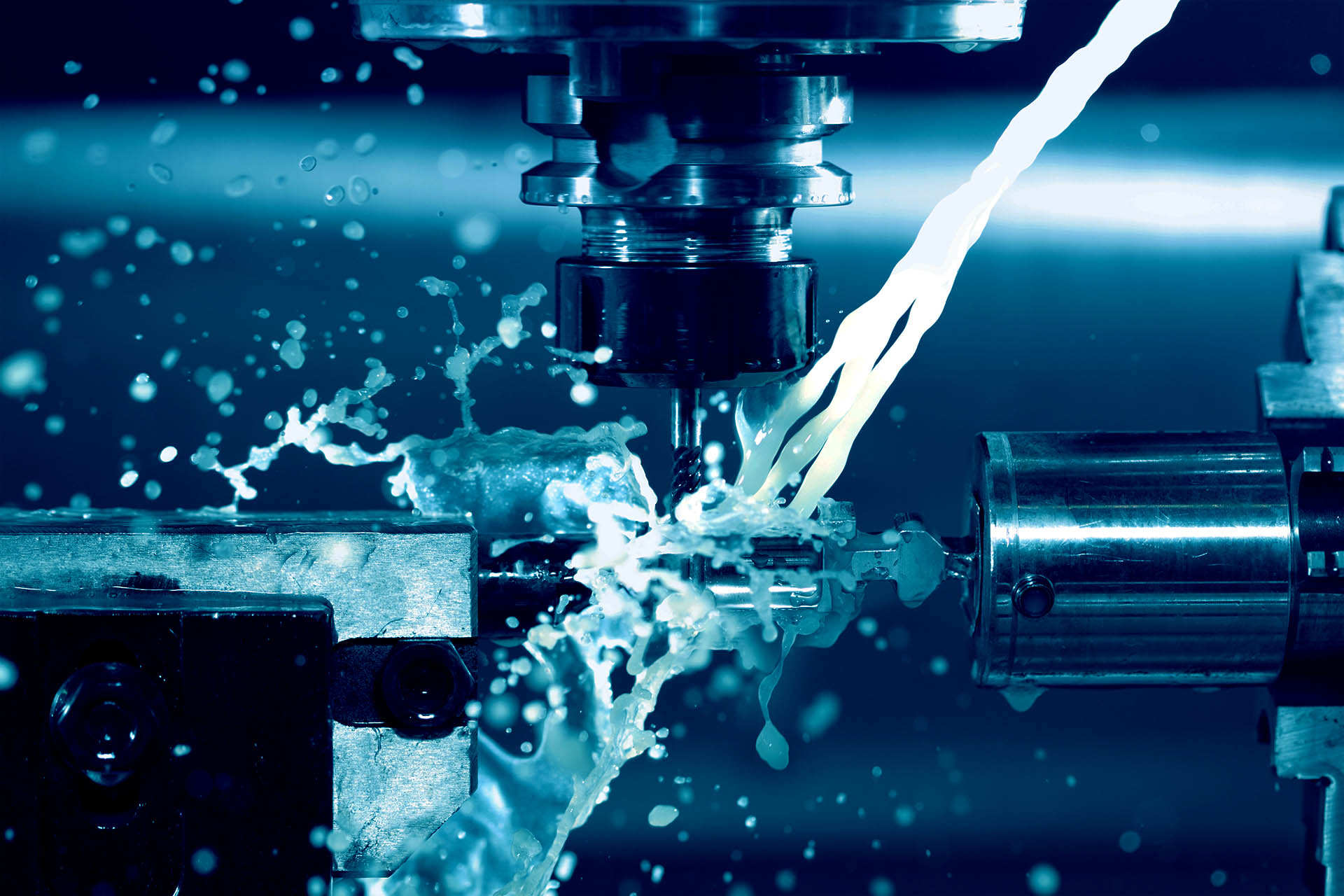

| CNC Lathe Machining

What is CNC Turning Machining?

CNC Turning machining involves securing the raw material rod on a driving headstock and rotating it while a fixed cutting tool removes material. This process is accomplished through the relative movement between the cutting tool and the raw material rod.

An automatic CNC Turning Machine can be integrated with a range of specific CNC machining operations, including:

- Turning

- Threading

- Boring

- Drilling

- Grooving

- Reaming

- Cutting

- Facing

- Parting

- Knurling

A precision manufacturing CNC machine with computer numerical control (CNC) is a powerful machine that can be equipped with advanced features such as highly precise CNC control, automatic feeders, coolant systems, and translation/rotary systems.

At Overland, we specialize in operating highly precise CNC Turning Machining Centers from renowned manufacturers in USA and China, including Nomura, Star, Moriseiki, Miyano, Takisawa, Chiah Chyun, and more. These machines are categorized into Fixed Head and Sliding Head Turning/Lathe Machining Centers, offering versatility and efficiency for various machining purposes.

TRAUB CNC Lathe

Would CNC Turning Machining be suitable for manufacturing my part?

CT-850 Machining center

Determining if a part can be made most cost-effectively on a CNC Turning machine involves considering the following factors:

- Largest OD: Compare the largest outer diameter (OD) of the part to theproduction quantity. If the part has an OD under 65mm, it may be suitable for higher volume mass production (over 1000 pieces). However, if the part has an OD larger than 20mm, it will need to be individually chucked during CNC machining, making it more competitive for lower quantity work, such as prototypes.

- Suitability for Swiss Screw Machine: If the CNC machining part has an OD under 20mm and requires high volume production (over 5,000 pieces), it may be suitable to run on a Swiss Screw Machine (also known as a CNC Automatic Turning/Lathe Machine). This option can be more cost-effective and offer high precision.

CNC Turning Lathe Machining Capability

Outer Diameter: 1-100 mm

Overall Lengths: 500mm

Tolerance: ±0.002 mm ( equal to 2 μm )

CNC Milling Machining Capability

Dimension: within 300 x 300 x 300 mm

Tolerance: ±0.002 mm ( equal to 2 micrometer )

Overland Engineering and Logistics Co., Ltd. was established in 2011. With over 13 years of overseas experience, we provide end-to-end solutions from inception to completion.

Hotline : +1 (314)377-4890

Phone

+1 (314)377-4890

oel@overlandind.com

Location

4338 Bridgeton Industrial Drive Bridgeton MO 63044 US

Quick Links

Customer Service

Subscribe Newsletter

Copyright © Overland 2024. All rights reserved.