Overland Engineering and Logistics Co

Get Consultation

+1(314)377-4890

- Need Free Consultation ?

Get Consultation

+1(314)377-4890

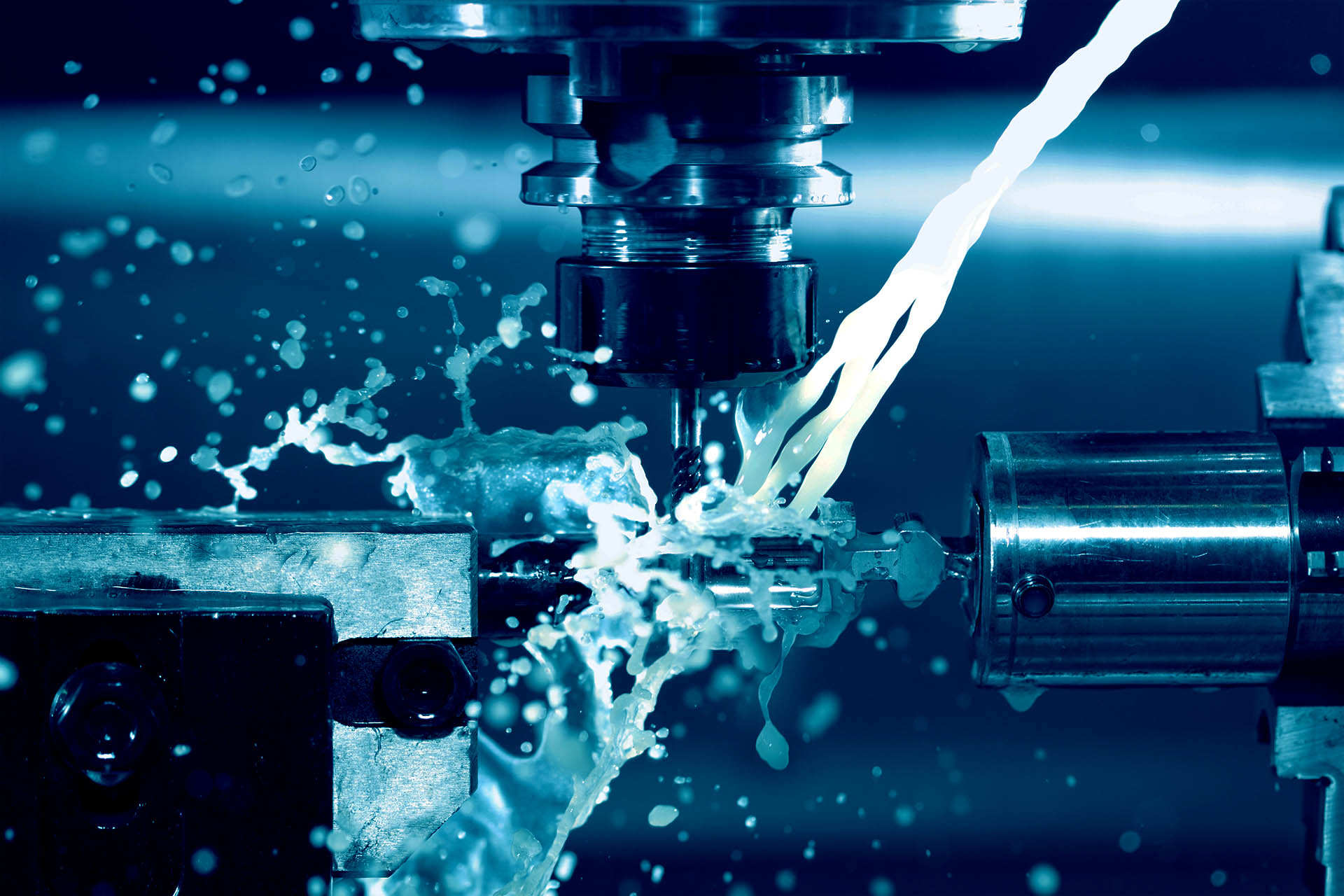

What is Stamping?

The stamping process involves the transformation of flat metal sheets into desired shapes using a tooling die, which comprises a top part and a bottom part. Once the tooling die is constructed, a raw flat sheet of metal is inserted into the mold, and a mechanical press is activated to create a component. This process allows for the efficient production of a large number of objects using the same mold, resulting in time and cost savings.

In the stamping process, several operations are typically performed, including blanking, bending, deep drawing, and embossing. Blanking involves using a blanking die to create a blank, which serves as the starting point for further production. Bending dies are used to deform or bend the metal sheet along a straight line. Deep drawing dies consist of multiple stages that gradually stretch the metal sheet to achieve the desired shape and thickness. Embossing dies are employed to engrave patterns or designs onto the metal sheet.

Metal Stamping

Our machining services are well-suited for producing sheet metal parts with a thickness range of 0.1-10.0mm.

-We have the capability to work with various materials, including brass, stainless steel, aluminum alloy, and carbon steel.

-Our services encompass a wide range of operations, such as bending, blanking, piercing, cutting, deep drawing, and more.

Stamping / Pressing Machining Capability

General Tolerance: ±0.05 mm

Overland Engineering and Logistics Co., Ltd. was established in 2011. With over 13 years of overseas experience, we provide end-to-end solutions from inception to completion.

Hotline : +1 (314)377-4890

Phone

+1 (314)377-4890

oel@overlandind.com

Location

4338 Bridgeton Industrial Drive Bridgeton MO 63044 US

Quick Links

Customer Service

Subscribe Newsletter

Copyright © Overland 2024. All rights reserved.