Overland Engineering and Logistics Co

Get Consultation

+1(314)377-4890

| Metal Stamping

Stamping Components Manufacturing Lines

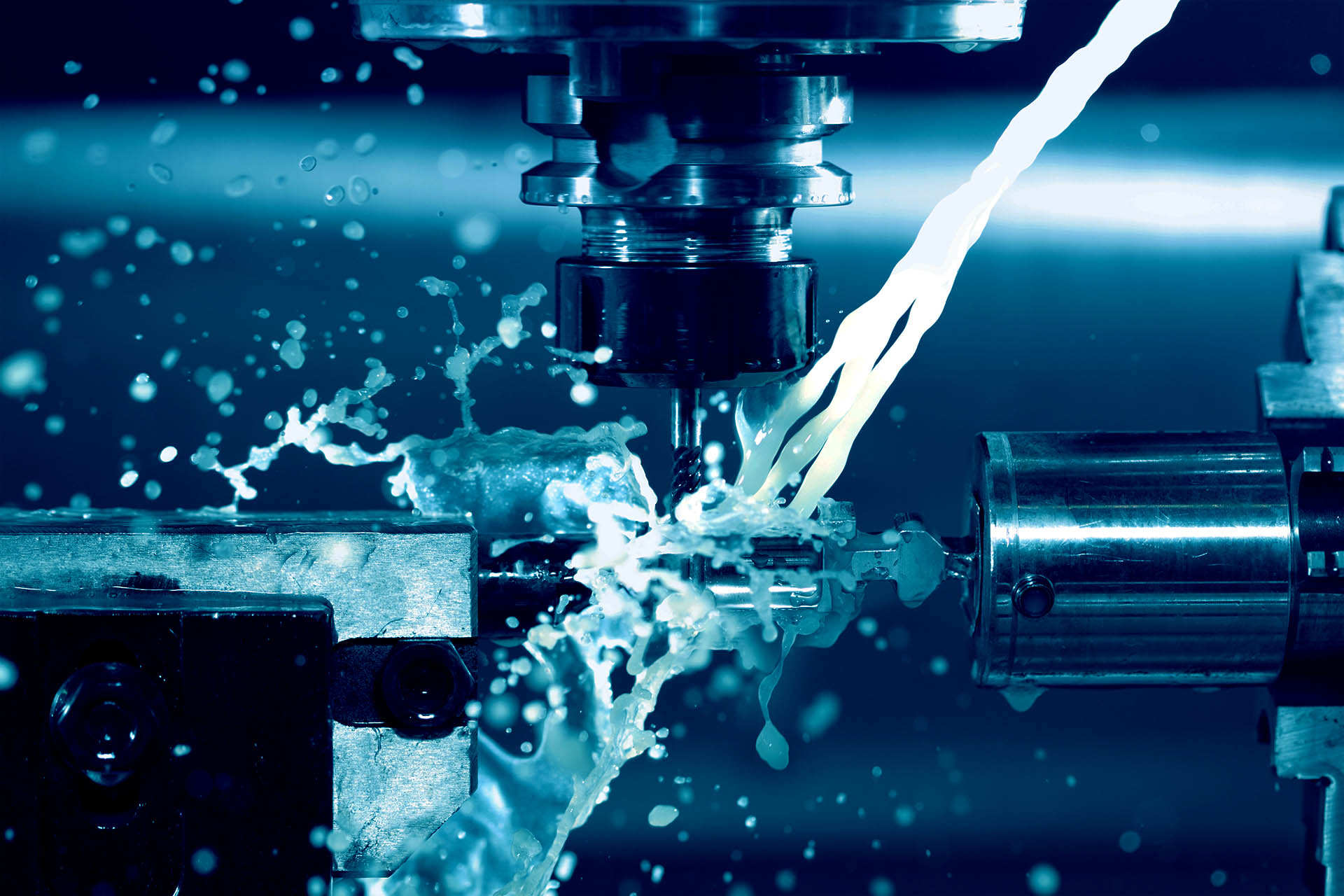

As a comprehensive machining services provider, we have expanded our capabilities by investing in a stamping facility equipped with high-speed presses, mechanical presses, and pneumatic presses ranging from 3T to 110T. This includes a dual-spindle pneumatic stamping machine with a tonnage capacity of 110 tons. With these resources, we are able to offer our clients a wide range of stamping production services, including deep drawing, blanking, bending, and more.

In addition to our stamping capabilities, we have further enhanced our production lines by incorporating NCT automatic punching, laser cutting, and laser welding services. These additional processes allow us to extend the scope of our stamping production lines, providing our clients with comprehensive solutions for their manufacturing needs.

What is a Stamping Components ?

A stamping part is manufactured using a stamping mold, which is designed to shape metal through processes such as blanking, piercing, drawing, bending, and embossing. Both single stage stamping molds and progressive stamping molds are capable of producing the desired metal form with each press stroke.

A single stage stamping mold is characterized by its simple structure and lower cost, making it suitable for single stamping operations in general.

On the other hand, a progressive stamping mold consists of a series of dies arranged in sequence, where a metal strip passes through each stage with every punch. While progressive stamping molds are more expensive than single stage molds, they are typically recommended for high-volume production or complex workpieces.

If you have a project that requires stamping, we encourage you to contact our team for a project review. Our engineers will carefully assess your requirements and provide detailed advice based on your specific needs.

- Metal Forming-Deep Drawing

Deep drawing is a sheet metal forming process in stamping where the material is radially drawn into dies using multiple punches. It creates complex shapes by transforming the sheet metal while retaining its integrity. Deep drawing is used when the depth of the formed part exceeds its diameter.

- Metal Forming-Blanking

Shearing is a cutting process in stamping that uses a punch and a die to create holes or profiles in a metal sheet.

- Metal Forming-Bending

In stamping, a common process is used to create V-shapes, U-shapes, or channel shapes in ductile materials, typically metal sheets.

Available Stamping Materials:

Copper | OFC, C11000 |

Brass | C2680 |

Phosphor Bronze | C5191 |

Stainless Steel | 304, 316 |

Aluminum Alloy | 5052 |

Overland Engineering and Logistics Co., Ltd. was established in 2011. With over 13 years of overseas experience, we provide end-to-end solutions from inception to completion.

Hotline : +1 (314)377-4890

Phone

+1 (314)377-4890

oel@overlandind.com

Location

4338 Bridgeton Industrial Drive Bridgeton MO 63044 US

Quick Links

Customer Service

Subscribe Newsletter

Copyright © Overland 2024. All rights reserved.